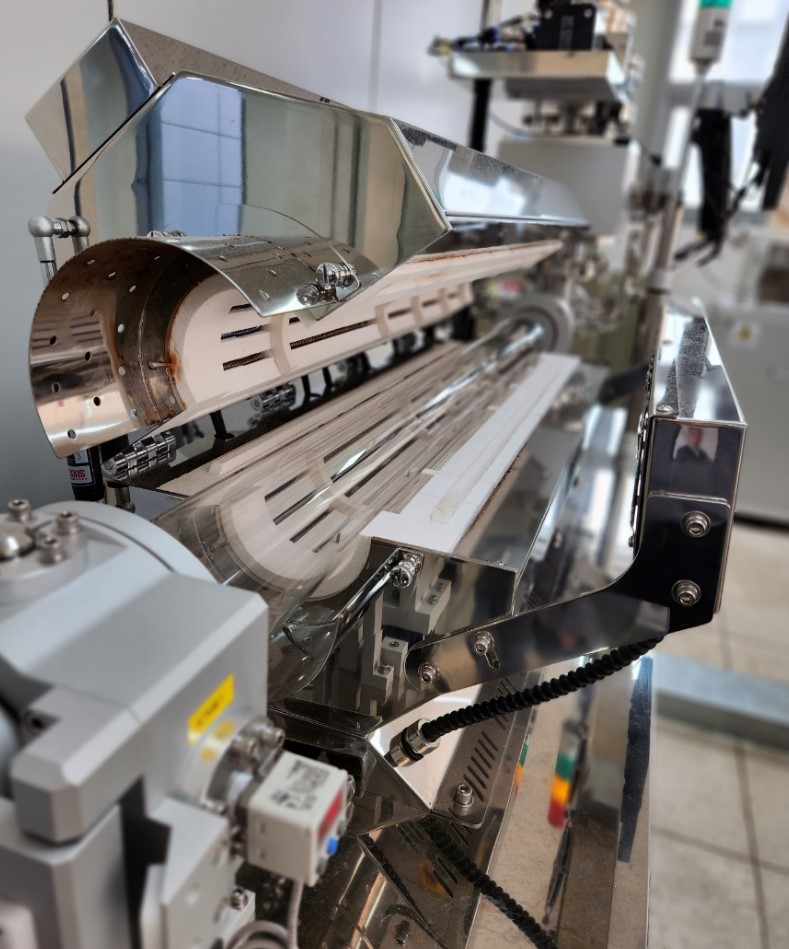

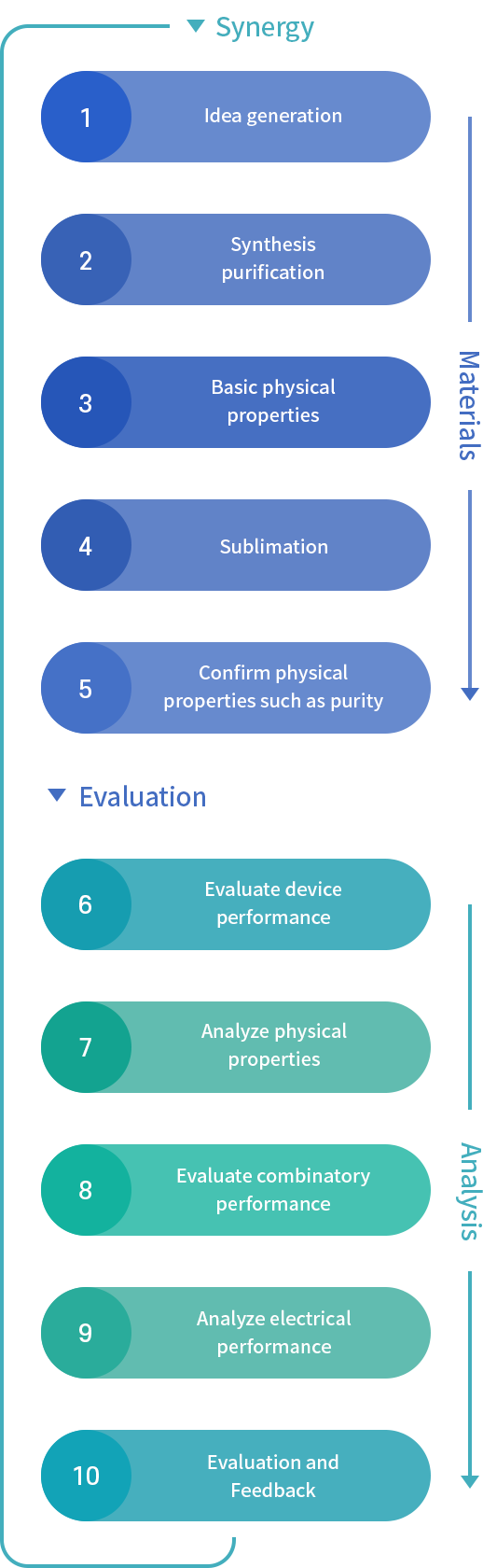

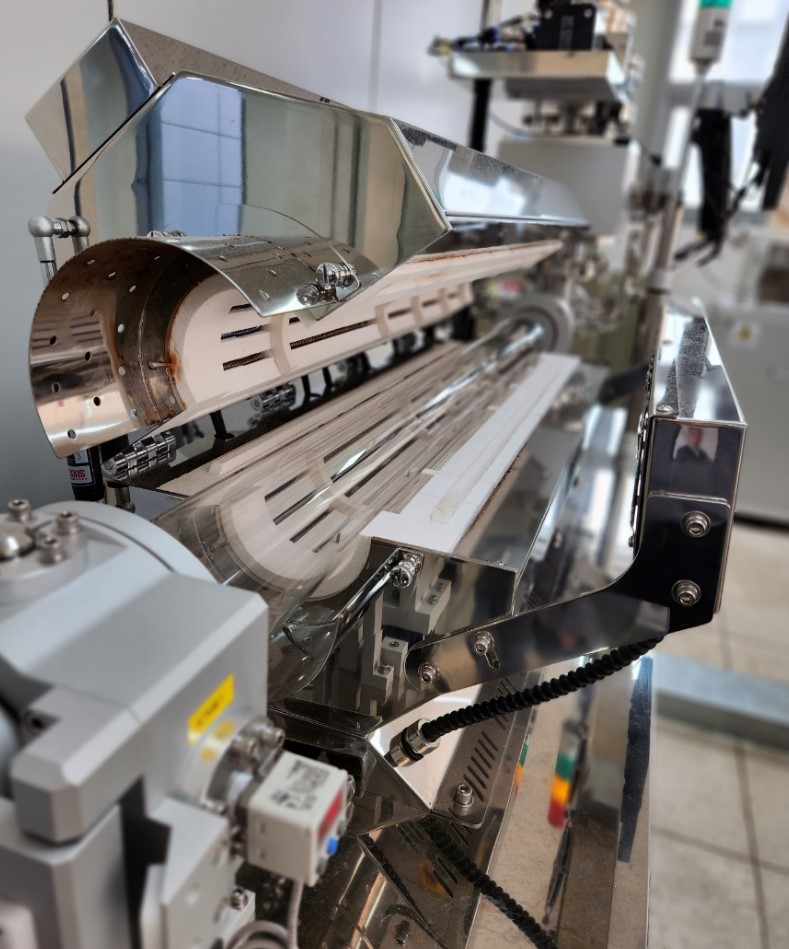

Synthesis is performed on the candidate structures which had been screened through simulation. This process requires complex and sophisticated multi-steps, sometimes up to 10 or more. Therefore, long-term accumulated experiences and know-how are of utmost importance.

During synthesis, numerous analyses on structure, purity, and optical characteristics are performed, simultaneously.